NEWS

AUGUST

THE FIRST BELARUSIAN DREDGING COMBINE REPLACED ITS GERMAN PREDECESSOR, WHICH WAS USED IN THE MINES OF SOLIGORSK FOR MORE THAN TEN YEARS

Industrial tests of the first mining combine produced in Belarus are taking place in the Soligorsk mines - "Umka-550" has already brought tons of potash ore to the surface, Belaruskali reported.

"Today, the first tons of potash ore were brought to the surface by the first Belarusian mining combine "Umka-550", - the company's Telegram channel said.

Belaruskali called the event a historic moment.

They recalled that "Umka-550" was produced by "Mashkhimprom", and the assembly of the combine was carried out at the underground mining section No. 7 of the first mine administration.

"It replaced the SL 300/400, which has been in operation since 2013.

The development of domestic machine builders is an analogue of the German predecessor," the company noted.

Currently, the combine is undergoing industrial tests, the purpose of which is to confirm the technical characteristics declared by the manufacturer.

"The mine is in no hurry to make forecasts regarding production indicators using the new equipment. But they are confident that the professionalism of the developers, together with the experience and knowledge of the production workers, give a good result. And the domestic industry receives highly efficient models of machines that are not inferior to foreign analogues," Belaruskali said in a statement.

The first Belarusian!

The presentation of the first Belarusian dredging combine took place in May this year - the machine successfully crumbled a concrete slab imitating a rock.

The Belaruskali press service then noted that the Umka-550 has the same parameters as the SL-300/550 combine harvester, which was previously assembled by the company together with German partners, but the localization level increased from 20 to 80%.

Umka-550 was created by specialists of the Soligorsk enterprise Mashkhimprom LLC in a year and a half. Subsequent machines are planned to be manufactured in 6-7 months.

Article taken from the news portal Sputnik Belarus

MAY

PRESENTED FIRST BELARUSIAN MINING MACHINE UMKA-550

At one time, Alexander Lukashenko initiated a project to manufacture a domestic combine for the extraction of potash ore. Mashkhimprom LLC presented the result of cooperation with Belaruskali LLC, which made it possible to fulfill the instructions of the Head of State as soon as possible.

The domestic mining combine "Umka-550" is the first import-substituting. It has the same parameters as the SL-300/550 combine, which was previously assembled by Belaruskali together with a German company, but at the same time the level of localization increased from 20 to 80 percent.

Mashkhimprom LLC specialists created an analogue in a year and a half. Soligorsk machine builders are ready to manufacture all subsequent Umka-550 combines in 6-7 months.

APRIL

Participation in the MiningWorld Russia 2024 exhibition

From April 23 to 25, our company took part in the 29th international exhibition of machinery and equipment for the extraction, processing and transportation of minerals MiningWorld Russia 2024 in Moscow, Russian Federation.

APRIL

We took part in the MiningWorld Russia 2023 exhibition

From April 25 to 27, 2023, our company will take part in the 27th International Exhibition of Machinery and Equipment for Mining, Processing and Transportation of Minerals at the Crocus Expo IEC, Moscow, Russian Federation..

JANUARY

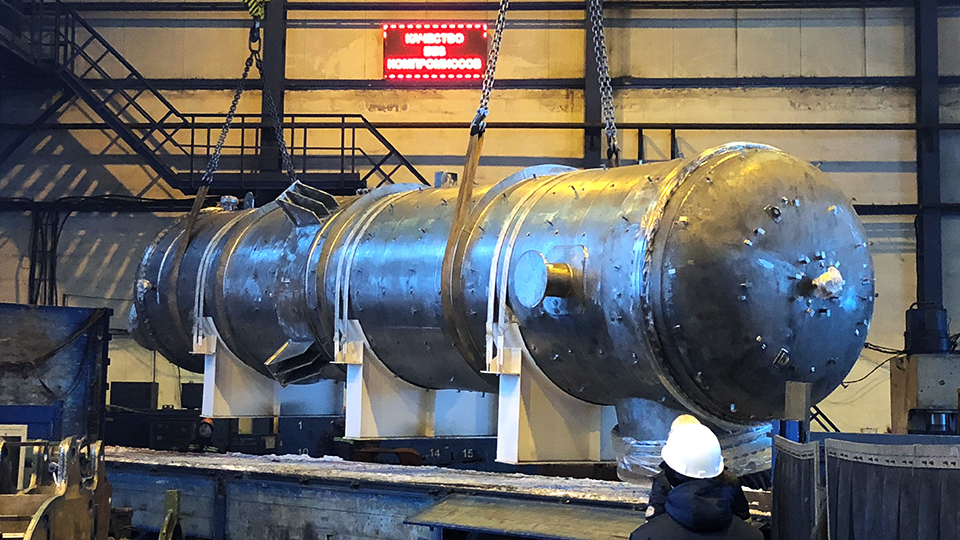

MASHKHIMPROM LLC has manufactured and conducted tests for tightness and strength of the surface condenser for Silvinite Processing Plant of PU4

The surface condenser is designed for heating the uterine lye as part of a vacuum crystallization plant with controlled crystal growth for the crystallization of potassium chloride.

Main technical characteristics:

length - 7500 mm

diameter - 1600 mm

number of tubes - 900

weight - 11 tons

material - Titanium "Grade 1"

DECEMBER

On New Year’s Eve, we successfully handed over a shock-reflective crusher type DR 10.20.

The impact crusher is designed for crushing pressed potassium chloride tiles in the first crushing stage of the granulation plant.

Feeding capacity, t/h - 180÷240

ДЕКАБРЬ

We manufacture a set of powered roof support sections with linear expansion 09/15 for seams with a small removable thickness of 1.15-1.45 m:

The mechanized supports will be operated as part of a mechanized complex designed for ore extraction.

Mechanized supports provides control of the roof in the stope and maintains it in a safe condition for the movement of personnel and equipment in the process of ore mining.

Main technical characteristics:

folded height - 900 mm

extended height - 1500 mm

top width - 1700 mm

section weight - 5870 kg

DECEMBER

On December 22, with the support of MASHKHIMPROM LLC, Umka Company LLC and Umka Project Organization LLC, a New Year’s boxing tournament among the strongest junior boxers of the Republic of Belarus was held in the city of Soligorsk

DECEMBER

We have mastered the production of centrifugal slurry pumps

NOVEMBER

It’s our 15th birthday!

For 15 years, MASHKHIMPROM has grown from a small company into a giant in the production of non-standard equipment and technological systems for the mining, chemical and oil industries, and has become a reliable partner in the production of construction and installation works and installation of metal structures. Throughout the time, we have been conquering the international and domestic markets not with the scale of production, but with quality!

APRIL

A horizontal centrifuge with a pulsating piston CPU-50 was designed and manufactured.

The pulsating centrifuge of the CPU-50 type is a filtering, two-stage, continuous operation. Designed to separate the product into solid and liquid phases under the influence of centrifugal force (dehydration).

The pulsating centrifuge is a stator, which is an oil tank, on which the bearing housing with the rotor shaft, pusher rod and bearings, the rotor drive and the hydraulic system are located. The technological chamber of the centrifuge consists of two perforated baskets, internal and external, in which slotted sieves are installed as a filter element. Baskets are located inside the casing, which is divided into several zones.

All parts of the centrifuge in contact with solid and liquid phases are made of stainless steel.

Main technical characteristics:

drum execution: 2-stage

drum diameter: 1120/1200mm

maximum rotor speed: 1000 rpm

pulsation frequency: 65/75 strokes/min

productivity (dry): not less than 50 t/h

product temperature: 26-50°С

overall dimensions WxHxL: 2280x1900x4430 mm

APRIL

We have made acceptance and started shipping the sets of the mechanized support section for the lava complex No. 3n-1 of the Berezovsky mine 1 PU JSC Belaruskali with an average take-out capacity of 2.35 - 2.4 m in the following compositions:

linear section of powered support with extension 16/25

powered support for end section with extension 16/25

coupling powered support with extension 16/25

MARCH

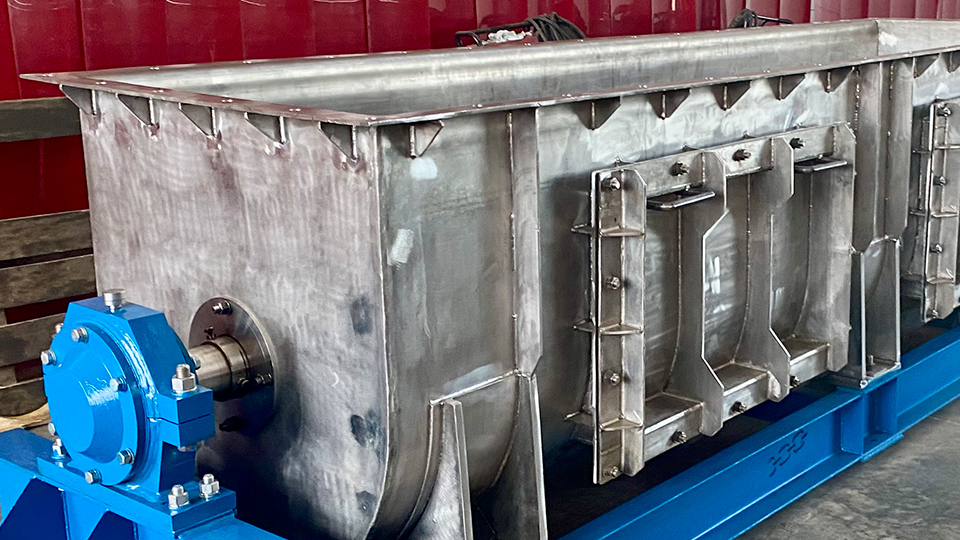

A screw mixer designed for the treatment of potassium chloride with reagents at SOF 4PU of JSC "Belaruskali" was manufactured and presented to the commission of JSC Belaruskali.

Brief technical characteristics:

fabrication material: 10Х17Н13М2Т

capacity: 300 t/h

overall dimensions: 1500 x 1200 x 6260mm

spiral diameter: 900mm

FEBRUARY

We manufacture cargo and passenger modules of mining machines for the mechanical repair shop of JSC Belaruskali.

BelKa-018A 5M for the transportation of operating personnel - 26 pcs.

BelKa-018A GL cargo-passenger version - 17 pcs.

From February to April, 14 modules for mining machines "BelKa" were manufactured and shipped.

MAY

We manufacture a screw solvent with a dewatering elevator designed for mixing silvinite ore with a dissolving lye, leaching potassium chloride from it and dewatering halite waste as part of a 900t/h processing line.

Parameter

Screw solvent

Dehydrating elevator

Performance:

by solid phase, t/h

900

900

by liquid phase, m3 / h

1700

-

Working pressure

for the filling

for the filling

Operating temperature, °C

95±3

95±3

Density of the dewatered halite dump in the elevator, kg / m3

1500

Degree of elevator's buckets filling, %

up to 85

Mass fraction of water in the dehydrated product, %

8÷14

Drive gear

ЦДН-710-50-33-ЦвхЦвых-У3

7Ц3-1505-80-33-ЦвхЦвых-У5

Electric drive motor

АОЗ-400М-8 У2 IM1001

АИР315М8 IM1001

The number of revolutions of the electric motor, rpm

750

750

Electric motor power, kW

250

110

V-belt transmission ratio

1,562

1,336

Operating part

Rotor

Bucket chain

Rotor length, mm

27760

Rotor mass, kg

29480

Rotor diameter, mm

3233

Rotor speed, rpm

6

Quantity of bucket, piece

44

Volume of a bucket, l

320

Weight of bucket chain, kg

20350

Linear speed of the bucket chain, m / s

0,58

Overall dimensions of the screw solvent with a dehydrating elevator:

length, mm

30298

width, mm

16855

height, mm

16392

Weight of screw solvent with dehydrating elevator, kg

259344

Noise level (max), dB

80

Service life of a screw solvent with a dehydrating elevator, years

11

Operating mode

Continuous

OCTOBER

The construction of the Belkali-MIGAO potassium nitrate production plant has been completed.

СЕНТЯБРЬ

On September 27, Prime Minister of Belarus Sergei Rumas visited MASHKHIMPROM LLC.

Prime Minister Sergei Rumas visited MASHKHIMPROM. The head of the Government was introduced to the production complex and told about the results of financial and economic activities.

MASHKHIMPROM LLC specializes in projecting, manufacturing, assembling of supporting steel fencing constructions and non-standard equipment for chemical, petroleum and mining industry.

The director of MASHKHIMPROM LLC Alexey Rabotayev tells:

— The main feature of our production is difficult and very labor-intensive technological process. It does not love fast paces and is difficult in welding as there are several modes of welding production. The equipment from titanium which we make is used in aggressive environments, and it allows our products to be resistant to abrasion. Today we have two production cases and if everything safely develops, then we will construct also the third, we will increase quantity of jobs by 30 — 50 specialists and, of course, we will buy the new equipment.

During the inspection of MASHKHIMPROM production Ivan Golovaty, General Director of Belaruskali, noted the uniqueness of ITS work:

— Today the enterprises are or vendors of some certain nodes, details, or the enterprises which release the equipment in a complex. Uniqueness of MASHKHIMPROM, in my opinion, that it is also the organization which performs installation and construction works because today each element of the equipment for its subsequent mounting is considered. And it allows including to reduce terms which are spent for mounting.

Speaking about MASHKHIMPROM, we cannot but mention the construction of a new plant for the production of potassium nitrate, as MASHKHIMPROM is the general contractor for the construction of a joint Belarusian-Chinese enterprise. Ivan Golovati explains:

- By the end of September we plan to finish the main installation and construction works. And in early October start commissioning works, after which the plant will be put into operation. Today, construction is carried out according to the Chinese project and using Chinese technologies. It was planned that some of the equipment would be supplied from China, it is about 40 - 50%, but in fact, taking into account the time frame at which we are building the plant, even Chinese colleagues did not have time to supply us with the necessary equipment. And here we were very helped by MASHKHIMPROM - the necessary parts from stainless steel, titanium were quickly created. And in general the construction takes place very quickly: from the planned 36 months the plant was built in a year.

The construction of this plant is very important for the industrial complex of Belarus, as the production of new potassium nitrate, including import substitution for the Republic of Belarus, will begin. At the first stage production will be about 80 thousand tons, at the second stage - 160 thousand tons. Potassium nitrate supplies are planned to Europe and China. After the project is fully implemented and production reaches 160 thousand tons, it will be about 5% of the world 's potassium nitrate production capacity.

Source: Издательский дом «Беларусь Сегодня»

Photo: Максим Гучек, БЕЛТА.

AUGUST

We are building a plant for the production of potassium nitrate with a capacity of 160 thousand tons per year

A new high-tech production is being prepared to be launched this year near Soligorsk. Our country will launch the production of chlorine-free potash fertilizers - without them, for example, it is difficult to imagine a good potato harvest. The product is in demand both in the domestic market and abroad. Deliveries are planned to the EU countries, Russia, Turkey. Read more about this in the plot of the TV channel "Belarus-1".

JULY

Powered roof supports "МХП-16/25» for mine lava "Б2-н-1» JSC Belaruskali (SPF-4PU) has been produced.

Mechanized support ensures the management of the roof in the clearing bottom and on the interfaces with drifts and maintaining it in a safe condition, fixing the lava depending on the adopted technological scheme for working off the clearing column.

The mechanized support will be operated as part of the mechanized complex, which is a combination of machines and mechanisms united by a common technological scheme, and intended for the extraction of ore in lava with a pillar system of development of a potash reservoir with a long clearing face. Output power - 1.9-2.45m.

The support section is supportive and protective, has a sliding width of 1600-2500 mm, an installation step of 1.75 m.

JULY

The pressure vessel “Secondary vapor condenser CO201” was manufactured, tested and submitted to the acceptance commission of Belkaliy-Migao LLC

The condenser is produced for the object “Plant for the production of potassium nitrate at the industrial site of the 4PU, JSC Belaruskali”.

OCTOBER

Construction of a new production building has been completed

he new production building with an area of 2448 m2 will increase the volume and improve the quality of products through the introduction of flexible robotic production modules, the organization of flexible automated production sites using the latest metalworking world brand equipment . It will also provide an opportunity to master the production of new equipment.

We are focused on the quality of our products therefore at each stage of production we strive to reduce the human factor to a minimum.

The new production building has a painting and drying chamber "C-PRO" with dimensions of 10x6x4 meters which will allow to prepare and paint the surfaces in accordance with the requirements of international standards.

The existing production plant, administrative buildings were additionally externally updated.

AUGUST

Solvent screw with elevator dewatering unit is complete.

The equipment has been delivered with a test assembly to the customer

silvinite processing factory 4PU JSC Belaruskali

Screw solvent with elevator dewatering unit as part of the production line is intended for leaching of potassium chloride from sylvinite ore. It consists of an auger solvent and a dewatering elevator.

APRIL

We manufactured a surge tank with a control assembly and handed over to the Customer JSC Belaruskali (SPF-4PU) 29.13.13.115.00.00.000 from titanium

The surge tank is designed to distribute the flow of saturated lye evenly to the Brandes type sedimentation tanks with the possibility of rate control.

The surge tank is installed in the existing chain of devices, taking into account their mutual arrangement without any changes in the technological process. The device is installed instead of worn out one.

MARCH

The project for NPO PASSAT LLC has been completed

We have produced four vertical surface condensers for vacuum crystallization setting with controlled crystal growth for crystallization of potassium chloride made of titanium Grade 1 at the silvinite processing factory 4 PU, JSC Belaruskali.

The surface condenser is designed for heating the uterine lye as part of a vacuum crystallization plant with controlled crystal growth for the crystallization of potassium chloride.

Lye feeds through the pipe space from the pump, through the intertubular space parallel steam is supplied. In the implemented scheme of the external counterflow, the process of heat transfer from the steam to the lye takes place, as a result of which the lye is heated up to a temperature of 63.9 °C.

Brief specifications:

outer diameter of the body - 2000 mm

length of the cylindrical part of the body - 10000 mm

number of tube bundle tubes - 2500 pcs. with the method of installation

rolling + welding

execution of covers - spherical

weight - 20 000 kg

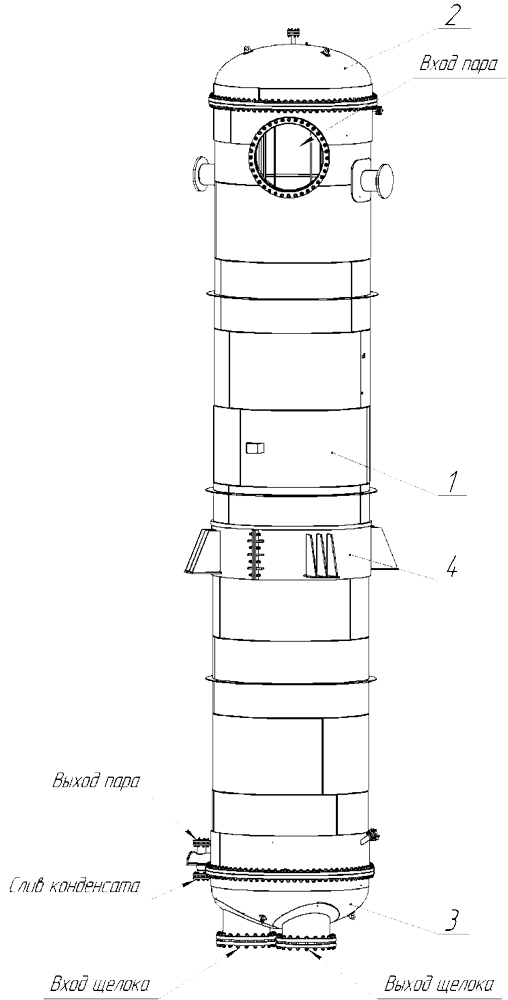

SEPTEMBER

The equipment for technical re-equipment of the vacuum-crystallization setting of the silvinite processing factory 4 PU, JSC Belaruskali

We have mastered the chemical-technological heat-exchange equipment - a heat exchanger made of titanium of 10 meters length and 2 meters in diameter.

The surface condenser is designed for heating the uterine lye as part of a vacuum crystallization plant with controlled crystal growth for the crystallization of potassium chloride.

Lye feeds through the pipe space from the pump, through the intertubular space parallel steam is supplied. In the implemented scheme of the external counterflow, the process of heat transfer from the steam to the lye takes place, as a result of which the lye is heated up to a temperature of 63.9 °C.

Краткое описание оборудования:

1 – distribution camera

2 – heat exchange chamber

3 – the camera cover

4 – fixed support

5 – mobile support

MASHKHIMPROM - QUALITY WITHOUT COMPROMISE!

Republic of Belarus, Minsk region,

Soligorsk district, Lyubanskoe highway, 32, 223710

Tel. / Fax: + 375 (44) 573 56 40

© 2025 All rights reserved